Fitness For Service evaluation of fibre-reinforced polymer (FRP) composite equipment hinges upon understanding how these tough, versatile materials degrade over time.

Unlike metals — which have relatively constant, predictable mechanical properties — in-service FRP composites change in ways that were not well understood until recently.

Those changes begin at the microscopic level and often go undetected long before any visible damage appears.

Consider this recent example:

The real cause of a chemical storage tank failure

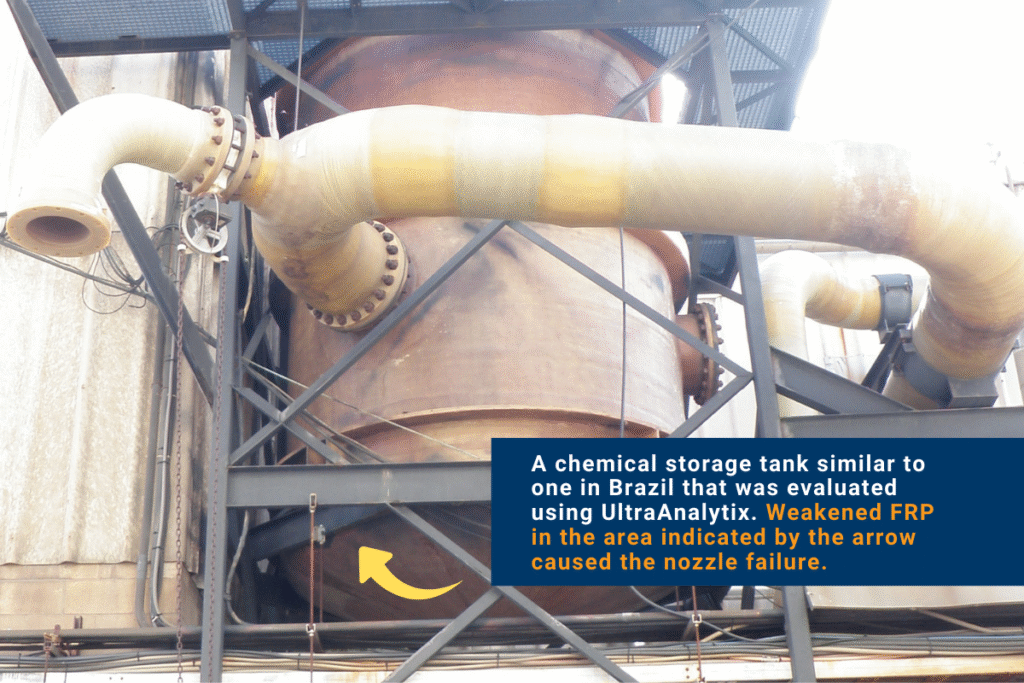

An engineer at a chemical production facility in Brazil reached out to UTComp to help investigate the damage to a storage tank that had failed. Experts on site were focusing on a nozzle, convinced that the failure was due to a manufacturing defect or poor nozzle installation.

However, using UltraAnalytix® NDE analysis, we found the failure was actually caused by structural damage to the bottom part of the tank, some distance from the nozzle.

Damage had been occurring for some time due to structural problems in the FRP. In addition to replacing damaged components, work needed to be done to reinforce the FRP.

Remaining Strength Factor is key

Using the UltraAnalytix system, the engineer was able to look beyond the obvious and determine the underlying cause of the tank failure.

This case also illustrates the importance of calculating Remaining Strength Factor (RSF) for FRP, which is the result of ongoing work to develop the new part for API 579-1/ASME-FFS-1, focusing on FRP Fitness For Service.

Based on the ultrasonic data alone, the tank appeared to be in pretty good shape overall. Looking at the corrosion barrier, it would have passed muster using conventional methods.

But by calculating RSF (which takes into account thickness, operating conditions and Polymer Damage Status), we found the equipment was well below the allowable RSF value even though it appeared to be in good condition and was operating in a relatively benign chemical environment.

How can that be?

Damage progression in FRP is more complex, less predictable than in metals

First of all, as soon as FRP equipment is turned on, as soon as you apply a load or pressurize it or put it in a hot room, you start to change it — that is, damage it.

That’s why FRP construction codes cannot predict how the material will behave after the equipment is in service.

Second, FRP composites exhibit distinct damage progression patterns due to their unique properties.

Third, changes to the FRP’s mechanical properties, especially the strain at failure, occur at different rates in the polymer components and in the fiber reinforcement components.

Fourth, the kinds of overt damage or flaws that affect Fitness For Service of steel — such as thickness loss due to corrosion — are almost irrelevant to FRP.

Finally, different polymers will behave and perform differently under load due to their molecular structure, flexibility and operating environment.

All of the factors above make damage progression in FRP more complex and less predictable than in metals. This has made evaluating the condition and reliability of FRP equipment more difficult, and helps explain why development of the new part for API 579-1/ASME-FFS-1 is critically important for our industry.

FRP loses elasticity over time

Steel is a homogeneous material that generally fails in a ductile manner, with a predictable yield point, a period of plastic deformation, and then fracture.

Its failure modes are well-understood, and Fitness For Service evaluation is relatively straightforward using established construction and inspection codes.

On the other hand, FRP composites are made from distinct components — resin and glass / fiber reinforcement. Each component has unique mechanical properties which change at different rates over time.

Damage progression is influenced by factors such as resin type, fiber orientation and manufacturing inconsistencies. Damage to FRP occurs in multiple stages, starting in the resin or matrix, and as it progresses the material loses elasticity, potentially resulting in what appears to be a sudden failure.

Damage to FRP happens before you see the crack

With metals, inspectors can identify various types of damage or defects such as thickness loss, blisters, gouges and cracks to draw conclusions about the equipment’s Fitness For Service. Using standard consensus methods, they can determine whether a crack or some other damage is likely to lead to a failure.

But in FRP, Fitness For Service is determined by what happens before the crack. The crack occurs as a consequence of a failure in the polymer that has already happened. The trick is identifying and assessing the extent of the underlying polymer damage.

A crack might not indicate that your FRP equipment is about to spring a leak or fail catastrophically. But it does show that damage has progressed in such a way that it may get there sooner or later.