UTComp is introducing a new UltraAnalytix® non-destructive testing report format with a material status colour code system that identifies the current condition of fiber-reinforced plastic (FRP) and composite assets and predicts future performance.

UTComp is introducing a new UltraAnalytix® non-destructive testing report format with a material status colour code system that identifies the current condition of fiber-reinforced plastic (FRP) and composite assets and predicts future performance.

UTComp first began to issue UltraAnalytix inspection reports for FRP assets in 2008, and has regularly updated the format to improve clarity and ease of implementation in response to feedback and requests from asset owners and licensees.

Over the years, we have also made significant improvements in our analysis capabilities for FRP and other composite materials, including the use of artificial intelligence to evaluate the probable trajectory of changes affecting the reliability of industrial equipment made with these materials.

Effective October 18, 2021, all UltraAnalytix reports will include the Material Status colour code system, which enhances our practice of providing straightforward and objective assessment of the current condition of composites and FRP assets using non-destructive testing technology. The colour codes, as depicted in the Material Status legend on the reports, are based on a prediction of the condition of the FRP for the next six years. (The maximum time recommended between UltraAnalytix inspections is three years.)

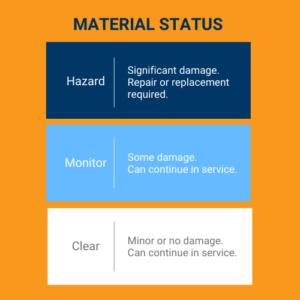

There are three Material Status categories as follows:

- Hazard (dark blue) indicates that significant damage has been identified. Repair or replacement is required.

- Monitor (light blue) indicates that some damage has been identified. The asset can continue in service.

- Clear (no colour) indicates that there is minor or no damage detected. The asset can continue in service.

The Material Status colour code system is also supported by further explanation available in the Analysis and Discussion section of each report.

Corrosion barrier evaluation

In addition to determining the overall status of the equipment, UTComp will also provide information and a Material Status code for the condition and extent of damage found in the corrosion barrier, if this information is available. This information will provide asset owners with the opportunity to make decisions based on a combination of corrosion barrier condition and full-thickness FRP condition.

UltraAnalytix reports will continue to include recommendations to optimize the lifetime cost of FRP equipment.