FRP Tank Inspection (Pulp & Paper Seal Tank Case Study)

UltraAnalytix® FRP tank inspection results showed that the thickness and condition of the FRP in a pulp bleaching vessel were adequate to postpone scheduled relining

BACKGROUND

The Owner Company operated a pulp and paper mill in British Columbia, Canada. Five seal tanks are used in the bleach plant, three of which contain chlorine dioxide filtrate. Chlorine dioxide is particularly corrosive to FRP, and often results in loss of FRP thickness.

Two of the three chlorine dioxide filtrate tanks were relined internally after 20 years in service based on internal visual inspection. The third chlorine dioxide filtrate tank (Seal Tank 15) is 28 years old and has never been relined.

The previous FRP tank inspection had recommended relining of Seal Tank 15 since 2015 based on internal visual inspection, and relining was scheduled for the plant shutdown in March 2017. UTComp, Inc was hired to inspect Seal Tank 15 in advance of the scheduled plant shutdown.

SOLUTION

UTComp visited the client’s site to conduct UltraAnalytix® FRP tank inspection, including External Inspection and UltraAnalytix® data collection and post-processing analysis. Internal Inspection is not required for UltraAnalytix® inspection, so system shutdown and confined space entry was not required. The inspection was conducted with the plant in operation.

CASE STUDY

The UltraAnalytix® analysis of the inspection data revealed minor damage to the corrosion barrier with no significant loss of thickness. The condition and thickness of the FRP was acceptable for continued service, even with conservative treatment of the inspection data. The client followed UTComp® recommendations that the vessel remain in service without relining, and be scheduled for next inspection in three years, thus saving the client significant repair costs. The remaining service life of the vessel at the time of inspection was estimated to be 29 years.

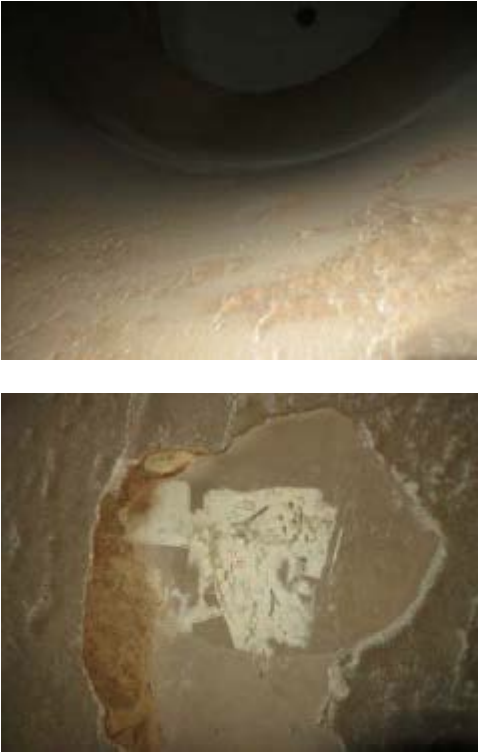

Condition of internal surface from previous inspector’s entry

Overall view of seal tank

View as a PDF

CASE STUDY: SEAL TANK 15 | OWNER: Pulp and Paper Mill

FACILITY LOCATION: Somewhere, BC | EQUIPMENT NAME: Seal Tank 15